Table of Contents

The Impact of Bamboo Tissue Products

Online, bamboo tissue products – particularly toilet paper – are experiencing a surge in popularity. With a wide range of options available, these products are attracting both price-conscious shoppers and eco-conscious individuals who value softness. Industry analyst Gregory Grishchenko examines the future of bamboo tissue production in America, as China ramps up its manufacturing efforts.

Changes in the Tissue Market

Almost a year ago, the outbreak of the Covid-19 pandemic led to a sudden surge in demand for tissue products. Major grocery chains across the US quickly restocked their shelves with pre-pandemic varieties from local brands. Interestingly, bamboo tissue, which has experienced explosive growth in online trade, did not have a prominent presence in American retail outlets at that time. However, this year, the Babo toilet paper brand, made from unbleached bamboo tissue, made an appearance at several CVS pharmacies in Florida.

CVS Pharmacy, the largest pharmacy chain in the United States with nearly 10,000 locations, offers household items, including tissue goods, among its merchandise. Babo brand supplier, Vanov Group, hails from the bamboo-rich Sichuan province in Southwest China, known for its rich bamboo vegetation and as the homeland of giant pandas.

Solid Bamboo Production Base

Sichuan province is currently a leading source of bamboo pulp, with an annual production capacity of nearly three-quarters of a million tonnes. Vanov Group utilizes bamboo pulp as the raw material to produce unbleached tissue products, such as toilet paper and napkins. The company has established its US sales office in New Jersey and claims an annual capacity of 200,000 tonnes of bamboo pulp. According to their website, they employ over 3,000 people across three factories.

Due to such a solid production base, their products in the US can afford a nominal profit margin, despite shipping and handling expenses.

Presence of Other Bamboo Tissue Brands

Other bamboo tissue brands have also made their way into major US chains. Target offers unbleached bamboo toilet paper under the brand name Caboo, while Costco has a similar brand called Reel.

However, as the tissue production crisis eased, major brands and private labels resumed full volume deliveries. It appears that bamboo toilet paper did not always meet consumers’ cost/value expectations during the early months of the epidemic and often remained the only product left on shelves in the tissue product aisles. As a result, bamboo toilet paper moved back to online platforms.

Above: Bamboo growing in a US restaurant

Challenges of Switching to Non-Wood Tissue

There are two categories of raw materials for tissue production: wood and non-wood fibers. Among wood fiber materials, recycled paper is considered to be the most eco-friendly tissue paper option as it uses no new resources and utilizes materials that would otherwise go to waste. However, for many consumers, the use of waste paper as a source is unappealing due to the presence of process bleach and chemicals used to make the product safe and attractive.

Bamboo, as a raw material for tissue production, presents several challenges in the stock preparation process, especially for refining. Bamboo pulp has shorter fibers compared to virgin wood, making it structurally weaker. Refinery technology is applied to bamboo biomass during the pulping process to preserve the flexibility of bamboo fiber. This requires lower flow, higher motor power, and additional apparatus to meet the raw material specifications for tissue production.

Many newcomers in the premium bamboo tissue market have emerged alongside established brands like Charmin, Angel Soft, and Cottonelle. Some brands achieve competitive “whiteness” using a mild bleaching process known as Totally Chlorine Free (TCF). These brands use environmentally friendly bleaching agents such as oxygen, ozone, hydrogen peroxide, and biological enzymes.

Silk’n Soft, on the other hand, goes a step further to whiten its 3-ply toilet paper. Their manufacturing plant processes Elemental Chlorine Free (ECF) bleached sulfate bamboo pulp, replacing chlorine with chlorine dioxide gas. Although chlorine dioxide is far less toxic than chlorine, it can still have long-term harmful effects on humans.

The Power of Greenwashing

In recent years, American shoppers have become more ecologically aware, leading to a growing number of online enterprises selling bamboo tissue products. These companies offer an impressive range of tissue grades, catering to a diverse consumer base ranging from price-conscious savers to eco-friendly enthusiasts and those seeking softness.

Bamboo tissue products, especially toilet paper, are gaining traction in the United States. Numerous direct-to-consumer companies with catchy names, such as Tushy, Betterway, Who Gives a Crap, Bim Bam Bo, Cheeky Panda, Noo Trees, and Smitten, promote eco-friendliness while using paper wrap (no plastic) and soy ink graphics (no solvents) to camouflage the light brown aesthetics of unbleached tissue.

Rebel Green, for instance, targets eco-conscious millennials by ensuring that their bamboo source for toilet paper does not originate from regions in China inhabited by pandas. Wholeroll toilet paper brand claims to use virgin bamboo pulp from responsibly “well-managed” bamboo forests certified by the Forest Stewardship Council (FSC). They do not use chlorine bleach, BPA, or any other harmful chemicals in their production process. However, the use of the term “organic” in advertising may be deemed excessive by health-conscious consumers who typically opt for wood-based recycled toilet paper, which generally has a lower price tag.

Cheeky panda: Pandering to the green devotees

Bamboo Tissue Production in China

Bamboo paper was initially processed at small factories in China, providing livelihoods to thousands of local residents. The Chinese government initially owned these bamboo paper industrial units, later awarding special permits to private business groups that took over bamboo tissue production. These groups were authorized to harvest and process bamboo plants, and their efforts were recognized as socially and environmentally beneficial for the country.

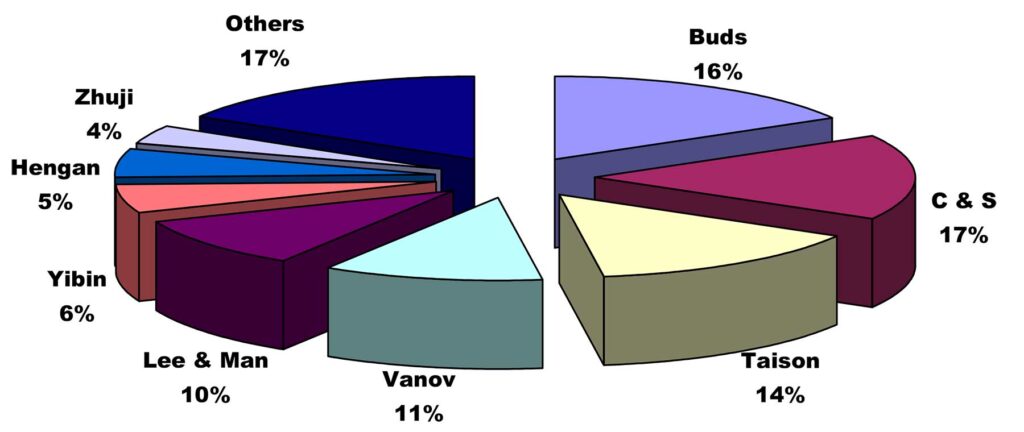

Over the last decade, the landscape of bamboo tissue manufacturing has changed significantly. Output volume from major players grew at the expense of smaller companies. Leading paper groups in China, such as Taison, Lee & Man, Vanov, C & S, Hengan, and Yibin, have made bamboo tissue production a vital part of their business strategies. They have replaced outdated machinery with state-of-the-art crescent formers from leading Western suppliers like Andritz (Austria), A.Celli (Italy), Voith (Germany), and Valmet (Finland). In response to this transformation, smaller businesses face a choice between upgrading their equipment or facing bankruptcy.

Taison Group, one of the largest producers of paper, board, and tissue in China, planned to produce half a million tonnes of bamboo tissue annually by 2020, making it one of the key bamboo tissue processors in the country. Taison Group implemented modern tissue machines from Andritz in paper mills in Suzhou (Jiangsu Province) and Chishui (Guizhou Province) for bamboo tissue production. These tissue machines, with state-of-the-art technology, can also process conventional wood-based or recycled fiber pulp.

Lee & Man Paper Manufacturing, based in Hong Kong, is a top supplier of paper products in the Chinese market, specializing in paper packaging, particularly containerboard. The company has shown interest in tissue products and has purchased nine Advantage DCT 200 HS crescent former tissue machines with stock preparation systems from Valmet between 2014 and 2018. These machines use virgin or bamboo fiber slush as raw material. Lee & Man’s Chongqing mill in the bamboo-rich Sichuan area mainly utilizes bamboo fiber slush. The combination of a steam-heated hood, Advantage ViscoNip press, and a cast Yankee dryer enables low energy consumption with a high production rate. They are also experimenting with different types of modern crescent formers from Voith (Germany) and Kawanoe Zoki (Japan) to produce unbleached tissue products using bamboo pulp.

Yibin Paper, located in Sichuan province, started as a manufacturer of disposable paper cups and bamboo boards. The company now aims to become China’s largest bamboo tissue paper producer, using exclusively bamboo pulp (while some bamboo tissue manufacturers add wood fiber pulp to improve strength and softness). Yibin Paper ordered five high-speed iDEAL tissue machines from A.Celli Group (Italy), equipped with a paper width of 2.85 meters, a production speed of 1,800 m/min, and a production capacity of 25,000 tons per year each. Four modern crescent formers are currently in operation, utilizing 16 ft. and 18 ft. Steel Yankee dryers alongside the latest-generation steam hoods.

Bamboo pulp processing capacity (China 2020)

Growing Bamboo in America

Considering sustainability, affordability, and global availability, bamboo reigns supreme. With its rapid growth rate of up to three feet per day and endless uses, bamboo is becoming an increasingly popular alternative to trees as a raw material. Eco-friendly bamboo toilet paper may potentially attract more individuals concerned about climate change. However, reducing carbon footprints also involves sourcing materials locally. Currently, all bamboo tissue goods in the US originate from China and the Far East, presenting a significant challenge.

Some commercial bamboo farming exists in the Gulf of Mexico area, where the Moso bamboo plant reaches its full size in the hot and humid surroundings. However, bamboo is not native to American soil and typically flowers only every 60 to 120 years before dying. Growing bamboo from seed or by dividing existing plants is challenging.

Above: This year Babo toilet paper brand appeared at several CVS pharmacies in Florida

Future Outlook

Nearly a decade ago, China started the trend of using alternative non-wood fiber resources for tissue products, including bamboo, wheat straw, sugarcane, reed, corn stalks, and hemp. Despite reducing imports of secondary paper, China remains the largest global market for imported wood pulp, accounting for 41% of global imports. Expanding the export of non-wood tissue products seems to be the logical next step. Although the bamboo tissue industry in China has faced challenges, including wood pulp price wars and numerous bankruptcies among non-wood fiber enterprises, it has emerged as the leading alternative tissue supply channel.

According to Pierre Bach from Hawkins Wright Research, non-wood fiber tissue products, primarily bamboo, have maintained a niche market, accounting for approximately 2.7 million tonnes worldwide over the past decade. Although China has established itself as a major exporter of virgin fiber tissue, with over 40% of the world’s production growth, the consumption of non-wood tissue is expected to gradually decline.

In the current context of Chinese-American trade relations, the perception of domestic consumers in the United States will play a critical role in the development of bamboo tissue sales. Consumer preferences, such as choosing between a coarse, brown feel versus a soft, white texture, may determine the future of bamboo toilet paper. It will likely remain a niche product, accounting for around 10% of imported tissue commodities in the US each year.

Article by Quill And Fox