Table of Contents

Laser cutting is a high-precision process that can create complex designs and patterns on paper.

The most common question when it comes to laser cutting paper is this- “How can you laser cut paper without burning it?”

Good process control and optimal parameters are the answers for laser cutting paper with no edge burns.

Laser cutting paper requires relatively less laser power (around 10-15W) and high cutting speed to perform a clean cut with no edge burns. The fast speed and high precision of a laser cutter allow cutting intricate designs with quick cycle-time, thereby providing high throughput.

In this article, I have discussed the process of laser cutting paper in detail, along with common challenges and ways to overcome those challenges.

Laser Cutting Paper – How to?

Laser cutter works by using a high-energy laser beam that burns, melts, and vaporizes the material.

When laser cutting paper, the paper absorbs the energy from the laser beam and vaporizes almost instantly.

However, the ability to catch fire almost instantly can result in overburning of paper. So, how to use a laser cutter to perform clean cuts on paper?

Performing a few test runs and maintaining good process control is necessary to attain a quality cut in paper with no or minimal burns.

There are various steps in the process of laser cutting paper, and each step needs to be regulated to achieve good-quality cuts.

Preparing the design

The process of achieving a good quality laser cut starts with a good design.

It also defines the sequence in which the design elements are to be cut by the laser.

The width of all the elements of the design should be greater than the thickness of the paper to maintain the structural integrity of the cut part.

When laser cutting intricate designs, the sequence of cuts should be set in such a way that the innermost pattern of the design is always cut first.

This is because once a part is cut it falls down to the work table and making further cuts on the piece that falls down is not feasible.

Using a good laser engraver/cutter software will simplify the process of making the design (CAD), converting the design into G-codes (CAM), and controlling the process parameters.

Furthermore, you can also use nesting software to optimize the design layout and maximize the utilization of material by reducing wastage.

CNC nesting software takes in the design and rearranges the elements in such a way that it uses minimal material while reducing tool travel and enhancing productivity.

Setting Optimal parameters

After preparing the design, the next step in the laser cutting process is to set the optimal parameters.

Power

The power of a laser cutter determines the ability of the laser to cut through the material.

Paper is generally a low-density thin material that does not require a high-power laser to cut through.

Using high laser power to cut paper will result in burnt edges, and since the paper is a flammable material, it can even cause fire hazards.

A low-powered CO2 or diode home laser cutter with a power rating of around 10-15 W is recommended for cutting or engraving paper.

However, the radiation of a CO2 laser has a wavelength of 10600 nm, which is readily absorbed by the paper.

Due to this reason, the cuts made in the paper by a CO2 laser cutter have superior quality to those produced by a diode laser.

Applying ink on the paper improves the absorption of the diode laser wavelength, thereby improving the quality of the cut.

Cutting Speed

The dwelling time of the laser determines the amount of heat supplied to the material at a particular point.

It directly affects the amount of material removed during the process.

The longer the dwelling time, the higher the heat supplied, and the higher will be the amount of material removed.

Paper, low-density material that can be laser cut easily, does not require extensive heat to be cut or engraved by a laser.

Longer dwelling time can result in overheating the paper leading to charring and overburning of the edges.

Therefore, a high cutting speed is recommended when laser cutting paper to keep the dwelling time to a minimum.

However, when cutting intricate designs, the laser head is constantly changing its direction, limiting the maximum speed that the laser head can achieve.

Due to this, the dwelling time increases and results in overburning of the edges even after setting the optimal parameters.

The solution is to perform intricate cuts with a lower power and speed setting.

Generally, a cutting speed of 6 ips (150mm/sec) with a power of around 15 – 20W is recommended for large cuts like the outer border.

Whereas a lower cutting speed of 1.2 ips (30mm/sec) with a power of around 9 – 10W is recommended for intricate cuts.

Focal length

Focal length adjustment plays a vital role in getting a clean and precise laser cut.

Adjusting the focal length affects the positioning of the focal point on the material, which in turn affects the laser’s spot size.

When laser cutting paper, it is recommended to use a 1.5″ lens to focus the laser on the paper’s surface to attain the smallest spot size.

Frequency

In laser cutting, the frequency determines the number of pulses of the laser hitting the workpiece per second.

Laser cutting at a high-frequency setting will result in more laser energy being delivered to the paper per second, and therefore more heat will be produced.

This increases the heat-affected zone (HAZ) and can burn the paper along the edge of the cut.

Although the optimum frequency setting varies from one machine to another, the sweet spot for frequency during laser cutting paper generally lies between 500 – 1200 Hz.

Resolution

Unlike laser cutting, where the laser slides across the material like a knife, the laser works in a continuous on-off pattern during laser engraving.

This on-off pattern of laser prints the required design or pattern in the form of thousands of tiny dots.

The resolution setting controls the number of dots printed by the laser per inch, and the optimal resolution for laser engraving paper is around 300-500 points per inch (PPI).

When laser engraving soft materials using diode lasers, the width of an engraved line can be wider than the diameter of the laser and result in overlapping of the adjacent lines around the edges.

This results in dark engraving with low contrast and less detailing of the engraved image.

Therefore, fewer lines per inch (under 270 LPI) are recommended to prevent overlapping the adjacent lines.

You can also use laser diodes with FAC lenses that produce uniform square dots to overcome such challenges.

Air Assist

When laser cutting paper, the air assist helps keep the cutting area’s temperature in control.

The compressed air blows along the cutting area, taking away the extra heat from the paper and minimizing the heat-affected zone.

To laser cut paper with no burn marks, it is desirable to set the air assist high and make provisions to hold the paper in place.

Work Table

Laser cutting paper produces a lot of smoke, and this smoke sometimes gets trapped under the paper and causes smoke stains on the back of the workpiece.

A pin table is recommended for laser cutting paper as it holds the paper at a distance from the surface of the work table and eliminates the chances of smoke getting trapped under the workpiece.

This allows easy clearance of smoke from the cutting area and reduces the smoke stains on the back of the workpiece.

Exhaust system

The smoke generated while laser cutting paper affects the performance of the laser by acting as a diffusing medium.

An exhaust system helps in the safe disposal of smoke away from the work area.

This improves the quality of the cut and regulates the temperature by generating a draft over the surface of the workpiece.

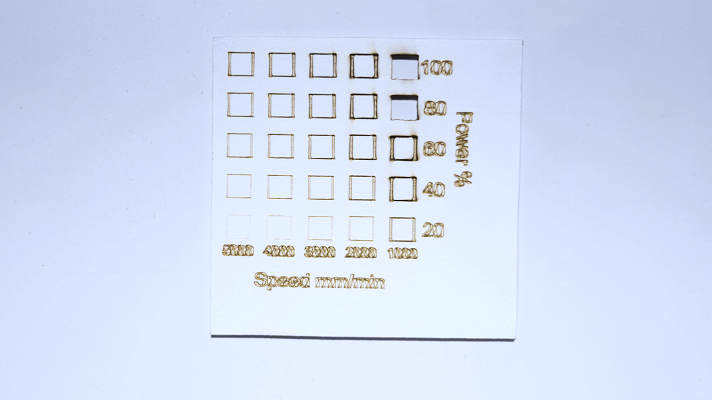

Performing Test Runs

The optimal parameters for laser cutting paper depend upon the laser cutter and the type of paper to be cut.

These parameters vary from one setup to another and require a few test runs to set them right.

The optimal parameters discussed in this article are more like guidelines that you can follow to find the best settings for your setup.

Laser cutting paper is relatively easy, and even a low-powered diode laser, such as a 1.6W module of Snapmaker 2.0, can also be used for producing excellent cuts in thin paper.

To perform the test runs for finding the optimal settings of general and precision cuts, it is recommended to cut squares with sides of 0.8″ and 0.3″ respectively.

Laser cutting thickness and speed charts for paper provide a better overview of optimal laser parameters for different thicknesses of paper.

You can start by testing with the parameters provided in the chart and record the effect of slight variations until you get the perfect cut with no edge burns.

Executing The Process

After performing the test runs and finding the optimal parameters, you can begin the process.

Although the process of laser cutting paper is very safe, it is recommended to follow the laser safety protocols and wear safety glasses when executing the process.

Furthermore, paper is a flammable material, making it necessary to keep an eye on the process to avoid fire hazards.

Types of Paper Suitable For Laser Cutting

There are various types of papers available, and almost all papers are suitable for laser cutting.

Here are some of the most commonly used papers for laser cutting or engraving.

Copy Paper

Copy paper is the most commonly used paper found in almost every workplace and household.

It is a very thin (0.004″) sheet of paper generally used in printers and copiers.

Copy paper can be processed under a laser to produce clean cuts but is not generally recommended for laser engraving as it is extremely thin.

Bond paper

Bond paper is similar to copy paper but is more durable and has a thickness of around 0.005″ – 0.02″.

Laser cutting bond paper produces a smooth cut with no edge burns and is also suitable for laser engraving.

Two-ply paper

A two-ply paper consists of two sheets of drawing papers bonded together with one over the other.

It generally has a thickness of around 0.06″ – 0.09″ and produces smooth edges when laser cut.

Using two different colored sheets of paper allows adding contrast to the engraving.

The laser burns the top layer of the paper revealing the color of the sheet underneath and thereby providing a bright contrast to the engraving.

Cardstock

Cardstock is categorized as thicker than copy paper or bond paper but thinner and more flexible than cardboard.

It is available in various colors and is considered one of the most widely used papers in laser cutting projects.

Cardstock is also known as cover stock or paperboard and is generally used in making gift cards, invitation cards, customized scrapbooks, etc.

It produces excellent results for both laser cutting and engraving.

Cardboard

Cardboards are thicker than cardstock with greater strength but are comparatively less flexible.

Laser cutting cardboard produces clean cuts and is highly suitable for cutting complex geometries as its high strength supports even the most intricate elements of the design.

Corrugated Cardboard

Corrugated cardboard consists of layers of corrugated sheets and linear sheets of cardboard.

It has high strength and is most commonly used in packaging or storage boxes.

Laser cutting corrugated cardboard produces clean cuts with a good surface finish.

However, corrugated cardboard throws up some challenges during laser cutting and is considered the type of paper that is most difficult to cut/engrave by a laser.

Laser Cutting Corrugated Cardboard

Corrugated cardboard is generally thicker than other paper types and is difficult to process under a laser.

The difficulty in laser cutting corrugated cardboard does not mainly arise due to its thickness but due to its construction.

It consists of multiple layers stacked on top of the other, and each layer consists of a fluted or corrugated sheet between two linear sheets.

When laser cutting corrugated sheets, the smoke generated by the burning of the paper is entrapped in the corrugated layers below.

The smoke disperses the laser beam and lowers its ability to penetrate through the cardboard.

Using higher power increases the penetration ability of the laser, thereby overcoming the loss of laser energy by dispersion.

However, using high laser power can overburn the material and even start a fire.

Therefore, it is recommended to use Dot Mode with high laser power for laser cutting corrugated cardboard.

In Dot mode, the laser does not cut through the material continuously like a knife, but instead, it generates pulses of high-powered laser that vaporizes the material.

This reduces the heat-affected zone (HAZ) by reducing the dwelling time, producing clean cuts with no edge burns.

Advantages of Laser Cutting Paper

Laser cutting offers various advantages over traditional paper-cutting techniques.

Quality

The quality of cut produced by laser cutting paper is far superior to the traditional methods.

As the motion of the laser head is controlled by a computer, there is no scope of human error in the positioning of the cutting tool.

This results in high-quality cuts every single time.

Speed and Precision

The most dominating advantage of laser cutters over traditional cutting methods is their speed.

Once you prepare the design and set the optimal parameters, the laser cuts the paper at an extremely fast speed.

This characteristic makes it ideal for mass production, where you prepare the process once and cut the same pattern multiple times.

Furthermore, laser cutters have high precision and repeatability, which means they can be used to cut intricate designs that were otherwise impossible by traditional methods.

Non-Contact Process

Paper is a soft material that can be easily creased or crumbled under mechanical force.

The non-contact nature of laser cutting eliminates the risk of inducing any unwanted mechanical force in the paper workpiece.

Flexibility

A good laser cutter provides the flexibility to control the process parameters to perform laser engraving by the same machine without even the need to change the tool.

It can be used to engrave intricate designs on extremely thin sheets of paper with high contrast.

This makes laser cutting the best way to cut and engrave intricate designs on paper.

Challenges in laser cutting paper

Despite showing its dominance in laser cutting intricate designs at high speed, there are various challenges in laser cutting paper.

Due to these challenges, most users prefer a Cricut over a laser cutter for cutting paper.

Overburning

Overburning is easily the most common challenge faced during laser cutting paper.

The low-density and flammable nature of paper results in quick heat absorption and large heat-affected zone (HAZ).

Using a low-power laser with high cutting speed and good process control can overcome this challenge.

Smoke Marks

When laser cutting paper, the paper vaporizes while generating smoke.

This smoke gets accumulated on the surface of the material and stains the workpiece.

Using a high-pressure air assist will blow the smoke away from the cutting area, and a good exhaust system will safely dispose of the smoke.

Furthermore, using a pin table will elevate the workpiece from the surface of the work table and facilitate the easy clearance of the smoke away from the workpiece.

Work Holding

Paper is a flexible and lightweight material, making it difficult to hold it in place.

Generally, using magnets is the easiest way to hold the paper in place without blocking the working area.

Flashback

One of the major issues with laser cutting paper is the flashback.

In this phenomenon, the laser beam reflects off the worktable and strikes the back of the workpiece causing unwanted burn marks on the paper.

An easy way to tackle this problem is to add an extra sheet of paper as a sacrificial layer under the workpiece.

This sheet acts as a protective layer and prevents the flashbacks from reaching the workpiece.

However, the space between the two sheets of paper traps the smoke and results in smoke stains on the back of the workpiece.

It is recommended to use a pin table to elevate the workpiece from the reflective surface of the worktable and weaken the effect of flashbacks.

Laser Cutting Paper Projects

Paper crafting is one of the most inexpensive business ideas for beginners.

It has been around for a long time, but paper crafting has been revolutionized with the introduction of laser cutters.

Depending upon your budget, laser cutter, and design expertise, you can start making basic paper projects and level up with each project.

Greeting Cards

Who doesn’t love a personalized greeting card with a beautiful message?

Cardstock is most popularly used for making greeting cards.

It provides the required durability while maintaining the flexibility of the paper.

Laser cutting intricate designs and engraving a personalized image or message on the card makes it a very unique, attractive, and profitable project.

Some other projects in this category are wedding invitations, gift boxes, customized menus, etc.

Stencils

The ability to laser-cut intricate designs on paper makes it ideal for stencils.

Depending on the need, you can use a copy paper for a single-use stencil or cardboard to make durable stencils that can be used multiple times.

You can make customized designs on customer demand and increase the value of your projects.

Desk Accessories

Desk accessories made out of paper are not generally a popular project, but having a creative design and using high-strength cardboard can result in a profitable project.

Using innovative designs can turn simple items like pen holders, file holders, lamp shades, and other desk accessories into a profitable project.

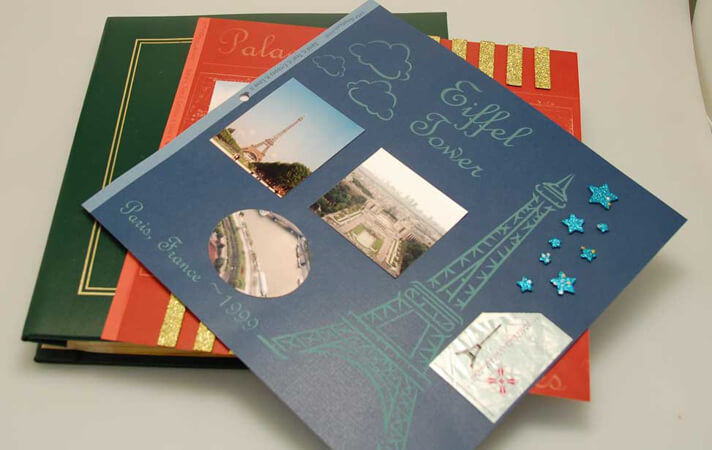

Customized Scrapbooks

Scrapbooks are one of the most profitable projects that can be made and customized using a laser cutter.

Using artistic designs and making customized pages on customers’ demand can make your scrapbooks unique and highly profitable.

You can also provide an option to engrave a customized photo on each page of the scrapbook to make it unique.

Art Work

Using a laser cutter to make paper art can be tedious and requires good knowledge about laser cutting and engraving different types of paper.

Depending upon your creativity and skills, these projects can be very profitable.

A laser cutter is an automated tool that can easily scale your projects and increase productivity, thereby increasing profit.

Best Laser Cutters For Paper

Depending upon the various factors such as power, speed, budget, and accuracy, these are some of the best laser cutters for paper.

Glowforge Plus

The Glowforge Plus is one of the best desktop laser cutter for paper and has a footprint of 38″ x 20.75″ x 8.25″.

It houses a 40W CO2 laser that can cut and engrave all types of paper up to a maximum thickness of 0.03″ (0.8mm).

Glowforge Plus offers a work area of 19.5” x 11” with a sleek design and an easy-to-use interface that ensures hassle-free use.

Glowforge plus has a spot size of around 0.008″ and a maximum resolution of about 1000 dpi.

All this combined with its high precision (0.001 inches) makes Glowforge plus ideal for cutting complex and intricate designs.

Furthermore, Glowforge plus has an inbuilt air-assist that will facilitate laser cutting paper with a smooth surface finish and no edge burns.

For cutting paper, you may also like to read – Glowforge vs Cricut: Which is a Better Choice?

Full Spectrum Laser Muse Core

Muse Core is a 40 W CO2 desktop laser cutter from Full Spectrum Laser.

It has a footprint of 32.3″ x 20.3″ x 8.5″ that offers a work area of 20” x 12” and a maximum working thickness of 2.5” with a removable bottom floor to fit in thicker workpieces.

It can be customized by including several add-on accessories like a water pump, air compressor, rotary engraver, exhaust fans, and additional lenses.

Muse core provides a maximum engraving resolution of 1000 dpi and including an air compressor in your kit will further improve its capability to cut and engrave paper.

The laser operation takes place in a completely enclosed structure which makes it safe to use.

It has a 7” touchscreen on the top to control the machine parameters and offers a maximum engraving resolution of 1,000 dpi.

The Muse Core laser cutter comes with a 1-year warranty which can be extended to 2 years at an additional cost.

Ortur Laser Master 2

Ortur Laser Master 2 has a footprint of 21.2” x 19.68” x 5.9” that provides a work area of around 15.5″ x 17″.

It is a low-powered diode laser with a budget-friendly price, making it ideal for beginners and DIY enthusiasts.

The Laser Master 2 offers various laser module options that provide a laser power of 1.6 – 5.5W and has a maximum engraving speed of 120 ipm.

Its low power and high engraving speed enable it to engrave photographs on paper with good contrast and minimal burns.

The low-power laser of Laser Master 2 can struggle to make clean cuts in corrugated cardboard but it can be used to cut thin sheets of paper with a good surface finish.

Ortur provides an optional safety enclosure for your Laser Master 2 that can be included in the kit at an additional cost.

A more detailed review of this laser engraver can be found here – Ortur Laser Master 2 Review

Final Thoughts

Laser cutting paper is by far the best way to cut and engrave all types of paper without creasing, folding, or crumbling the paper workpiece.

The challenges faced during the laser cutting paper can be efficiently dealt with by following the proper procedure and maintaining good process control.

It is recommended to perform test runs before the actual cut to ensure a perfect cut with no edge burns.

The ability to cut and engrave paper with high precision and speed makes it ideal for applications ranging from intricate artwork to manufacturing packaging boxes.

Laser Cutting and Engraving Other Materials

Check out these guides on laser cutting some popular materials.

Frequently Asked Questions (FAQ)

Can you laser engrave a photograph on paper?

Yes, you can laser engrave a photograph on paper. Using a low-powered laser at high speed is recommended to engrave a photograph on paper. However, raster engraving on very thin paper like copy paper can result in warping of the paper due to excessive burning. Therefore it is recommended to use cardstock or bond paper for laser engraving photographs.

Can you perform vector engraving on paper?

Yes, you can perform vector engraving on paper. However, it is necessary to maintain good process control as the paper is a soft material, and even a slight change in parameters can result in a through cut.

Can you laser cut a stack of paper?

Yes, you can laser cut a stack of paper.Laser cutting a stack of paper is similar to cutting a thick sheet of paper that requires higher laser power. However, using a high laser power will result in edge burns, and the smoke trapped between the layers of paper will stain the sheets. Furthermore, using high power on a stack of paper can cause fire and therefore needs to be monitored.